Dommestic water pressure boosting system.

For this project Moffat Technology designed and built a control panel to boost the incoming water pressure at a hospital from 50 psi to 80 psi so that the water demands of the second level could be met. This system works by controlling 2 pumps to maintain 80 psi. Depending on water requirements the system will just run one pump and vary its speed to maintain the 80 psi, or if there is a larger demand for water the second pump will start and vary its speed and together both pumps will maintain the 80 psi. An Allen Bradley pressure transducer was used to monitor the water pressure. An Automation Direct PLC was used to control the 2 Allen Bradley VFD’s. Also an Automation Direct 6 inch touch screen was used to display information about the system and to allow a user to change set points and manually control the system if required.

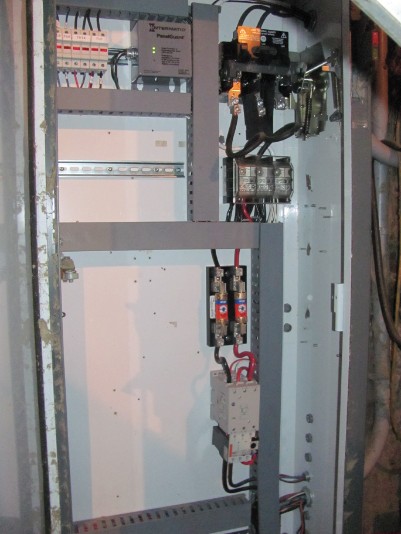

Automated Feeding System

Moffat Technology designed and built the control panel for this project. This is stage 1 of a 2 stage project to completely automate the feeding system. The scope of stage 1 was to run the mixer and the divert valve to feed to the new barn or fill the feed cart and to control the 5 conveyors that send the feed to the new barn. On the last conveyor in the new barn there is a plow that directs the feed off of the conveyor in to the manger. There are 3 Zones that can be feed from the conveyor. Stage 2 of this project will be to have a recipe that will automatically load the correct weight of each of the feed ingredients from each silo into the mixer which then can be mixed up and automatically sent out. For this project Allen Bradley contactors, overloads, disconnect and PLC were used. Also an Automation Direct 10 inch touch screen was used for the operator to control the system and enter set points into the system.